By Rehab Eldalil

Kendaka Upcycles was created out of its founders’ passion and blossomed out of its artisans’ spirit. A name historically given to Nubian queens, who were known to be brave, strong and wise, like the women artisans’ creators of its products. Essentially a factory/workshop for upcycling glass into creative products such as candle holders and mugs – Kendaka also seek empowerment for the women in its surrounding community. Located at Badr; a secluded industrial

city between Cairo and Suez where former residents of the earthquake areas in Cairo were relocated to. The community of Badr face seclusion and limited work opportunities due to their location, especially the women who seek safe and close jobs to provide for their families. The women in Badr community are considered the main pillar of the family and the superwomen behind this project.

This is the visual story of Kendaka.

This story is commissioned by Drosos Foundation.

Visual story by Rehab Eldalil

January – July 2019

Residential areas at Badr city are scattered around the factories with limited transportation options. Residents are forced to use public transport of microbuses and toktoks in order to reach to the other side of the Badr highway.

Overlooking the Badr highway, Subhy Hussein residential area is one of the social targets of Kendaka and is also one of the closest residential areas to the workshop where Kendaka aims to hire its arti- sans.

Factory streets in Badr city.

The infrastructure of Badr as an industrial city makes it impossible for its residents to easily reach their work venues by walking or biking. Adding into their expenses the public transport they need to

take in order to reach work, making it harder for women to find convenient jobs.

Kendaka workshop/factory overlooks a local kiosk run by one of the Subhy Hussein women and the entry point of the community.

Om Ahmed owner of the kiosk and the main entry point for Kendaka to reach out to the community poses in front of the factory and her kiosk.

“Kendaka owners trust me and rely on me to introduce them to the community and that is something that I take with pride because I feel I can help my community.”

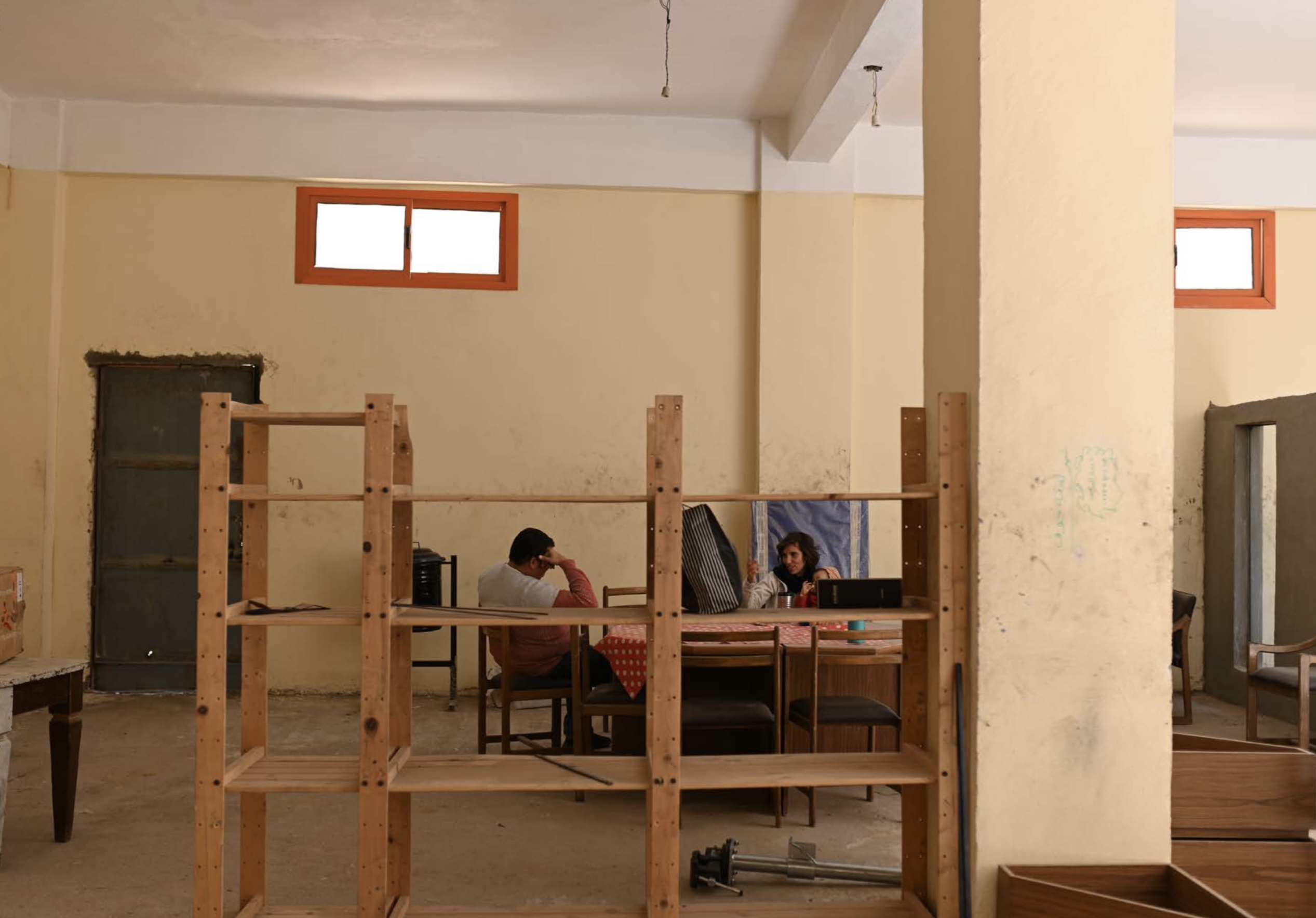

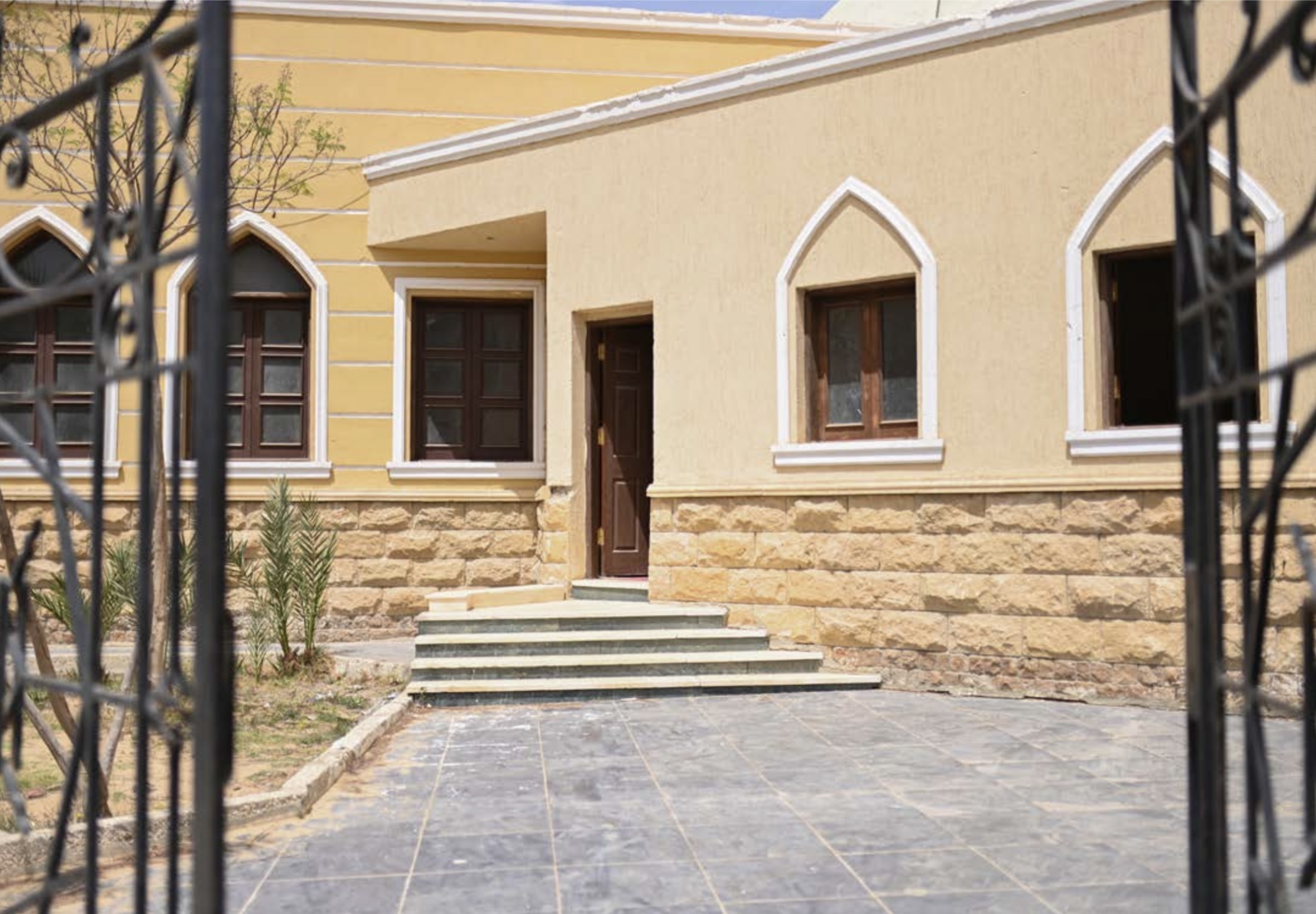

Renovations of the factory.

The blue windows of the old factory became an icon of the change to come. A before and after pho- tograph of one of the offices in the second floor of the factory.

The main workshop space in the ground floor of the factory. A before and after photograph.

The importance of family run deep within Kendaka, determined to empower the women artisans Ken- daka plans to open a nursery for the artisans’ children. Hana; Kendaka co-founder plays with her son in the factory entrance during renovations.

Community out reach plays a major role in hiring female artisans from the Badr community, the women need to feel safe and supported before agreeing to work at the factory. Catherine; Kendaka co-founder gives orientations to the community on weekly basis.

Community spaces such as youth centers, clubs and mosques help in the process of public out reach and promotion of the job opportunities at the factory.

Laila, one of the first artisans to join the team receives training from a Swiss glass expert. Laila’s mother found out about Kendaka from a friend of hers who attended an orientation, never has she

worked in a factory herself Laila was quiet worried. “Now I can not stand one day away from the fac-

tory” she states as she explains the major change she had working in the factory.

Ursina, demonstrates glass cutting by heat to Om Ahmed and other community members

Artisans are trained on both old and new technologies in glass upcycling. As the artisan team grows each new recruit must be trained on glass cutting, smoothing, polishing and sand blasting by an ex- pert trainer or an experienced recruit.

In less than three months of opening the Kendaka workshop/factory, 10+ female artisans have joined the team from all around Badr.

Glass items are collected from suppliers, washed and then divided into various upcycling use options based on size and type of glass. The glass then goes into the production process to be transformed into an upcycled product.

Facing a motivating challenge to finish 3000 glass pieces as the factory’s first commissioned order in a couple of months the women of Kendaka both artisans and founders created two working shifts to finish the order on time.

Amin; Kendaka co-founder discusses glass machinery for the workshop with Hana and Catherine.

Glass smoothing with water and metal discs.

Stencils are added onto the glass products before sand blasting.

“I’m really proud of the work that I do here and I feel I have the artistic skill for it, something that I only discovered when I came here.” Howayda’s section of final products.

Howayda, 22 year old graduated with a diploma in commerce has become one of the most experi-enced artisans in Kendaka and a peer trainer to new recruits. Howayda has only worked in pharma-

cies before joining Kendaka.

Kendaka founding team brainstorming brand names with designing team and the artisans – a collec- tive process that took weeks in order to develop a brand name that reflects the socio-eco imprint and aims of the project.

The growing pile of final products for the first and biggest commissioned order for the project.

Stencils are carefully removed after sand blasting.

Packaging of the final products consist of shredded paper from the commissioning company and sim-ple paper bags.

In celebration of finishing the first commissioned order, the founding team surprise the artisans with handmade candle holders as thank you gifts.

Written and photographed by : Rehab ElDalil

Bags & Clutches

Bags & Clutches